The heartbeat of modern diesel vehicles, the Common Rail Direct Injection (CRDi) engine, is a symbol of technological prowess. With its high-pressure fuel injection system, CRDi engines deliver enhanced performance, fuel efficiency, and reduced emissions.

This advanced technology injects fuel directly into the cylinders, igniting a powerful combustion process. While the CRDi engine’s precision and efficiency are commendable, it is important to acknowledge its higher initial cost, maintenance requirements, and fuel quality sensitivity.

Explore the world of CRDi engines and discover the driving force behind superior fuel combustion.

Key Takeaways

- CRDi engines revolutionize the way diesel engines function by injecting fuel directly into the engine cylinders at high pressures.

- CRDi technology offers numerous advantages over traditional fuel injection systems, including improved performance, enhanced fuel efficiency, and reduced emissions.

- The key components of a CRDi engine include the common rail, injector, electronic control unit (ECU), fuel tank, combustion chamber, and fuel accumulation.

- The advantages of CRDi engines include improved fuel efficiency, enhanced performance, lower emissions, reduced noise and vibration, and increased durability. However, they also have disadvantages such as higher initial cost, specialized maintenance requirements, fuel quality sensitivity, injector problems, and system complexity.

History of CRDi Engines

There have been significant advancements in the development of CRDi engines over the years, with numerous studies showcasing the quantifiable improvements in fuel efficiency, reduced emissions, and enhanced performance.

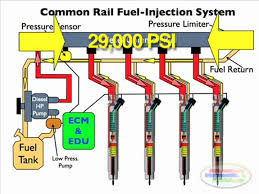

CRDi engines revolutionized the way diesel engines function by injecting fuel directly into the engine cylinders at high pressures. This advanced fuel injection system consists of components such as the common rail, injectors, electronic control unit (ECU), fuel tank, and combustion chamber.

The ECU collects data from engine sensors and calculates the optimum fuel injection timing and duration, resulting in precise fuel delivery and efficient combustion.

The advantages of CRDi engines include improved fuel efficiency, enhanced performance, lower emissions, reduced noise and vibration, and increased durability. However, these engines also have some disadvantages, such as higher initial cost, specialized maintenance requirements, fuel quality sensitivity, injector problems, and system complexity.

Key Components of CRDi Engines

The key components of CRDi engines include the common rail and injectors, which work together to deliver precise fuel injection at high pressures and ensure efficient combustion.

The common rail is a high-pressure fuel reservoir that stores diesel fuel at a constant pressure. It is responsible for supplying fuel to the injectors.

The injectors, on the other hand, are individual components for each cylinder that deliver fuel at high pressures. These injectors are controlled by an Electronic Control Unit (ECU), which collects data from engine sensors and calculates the optimum fuel injection timing and duration.

This precise fuel injection, combined with the efficient combustion process, results in improved performance, enhanced fuel efficiency, and reduced emissions.

The key components of CRDi engines play a crucial role in maximizing the benefits of this advanced fuel injection system.

Working Principle of CRDi Engines

The working principle of CRDi engines involves the direct injection of fuel into the combustion chamber at high pressure, resulting in improved performance and fuel efficiency. In a CRDi engine, fuel is stored in a high-pressure reservoir called the common rail.

The electronic control unit (ECU) collects data from engine sensors and calculates the optimum timing and duration for fuel injection. The injector then delivers a precisely measured amount of fuel at high pressure into the combustion chamber. This fine fuel spray mixes thoroughly with air, ensuring a more complete and efficient combustion process.

The improved combustion leads to enhanced power output, engine responsiveness, and fuel efficiency. Additionally, the CRDi system helps reduce emissions and engine noise and vibration.

However, CRDi engines may have higher initial costs, require specialized maintenance, and be sensitive to fuel quality.

Advantages of CRDi Engines

One of the key advantages of CRDi engines lies in their ability to deliver improved fuel efficiency and reduced emissions through precise control of fuel injection timing and duration.

The CRDi technology allows for the injection of fuel directly into the engine cylinders at high pressures, resulting in better combustion and optimized fuel delivery. This leads to enhanced fuel efficiency, reducing fuel consumption and saving costs for the user.

Additionally, the precise control of fuel injection timing and duration ensures that the fuel is burned more efficiently, resulting in lower emissions of harmful pollutants. This is particularly important in meeting environmental regulations and promoting cleaner air.

Overall, the ability of CRDi engines to deliver improved fuel efficiency and reduced emissions makes them a preferred choice for modern vehicles.

Disadvantages of CRDi Engines

Despite their numerous advantages, CRDi engines present certain disadvantages.

One major disadvantage of CRDi engines is their higher initial cost. The advanced technology and components used in CRDi engines make them more expensive to manufacture and purchase compared to traditional fuel injection systems.

Additionally, CRDi engines require specialized maintenance and expertise, which can be costly and time-consuming. These engines are also sensitive to fuel quality, meaning that they may experience issues if contaminated fuel is used.

Potential injector problems, such as wear and malfunction, can affect the engine’s performance. Lastly, the complexity of the CRDi system may result in complicated repairs, requiring skilled technicians and specialized equipment.

Despite these disadvantages, the numerous advantages of CRDi engines make them a popular choice in the automotive industry.

Applications of CRDi Engines

Our company has been exploring various applications of CRDi engines in order to maximize fuel efficiency and reduce emissions in our fleet of diesel vehicles.

CRDi technology has proven to be highly effective in achieving these goals. By injecting fuel directly into the engine cylinders at high pressures, CRDi engines ensure precise fuel delivery and efficient combustion. This leads to improved fuel efficiency, enhanced performance, and lower emissions.

The advantages of CRDi engines make them ideal for a range of applications, including passenger cars, commercial vehicles, and heavy-duty trucks. Additionally, CRDi engines offer benefits such as reduced noise and vibration, increased durability, and compliance with environmental regulations.

As we continue to explore the applications of CRDi engines, we aim to further optimize our fleet’s fuel efficiency and contribute to a cleaner environment.

Conclusion

In conclusion, the Common Rail Direct Injection (CRDi) engine has revolutionized diesel engine technology with its advanced fuel injection system. Despite some drawbacks, such as higher initial cost and specialized maintenance requirements, the CRDi engine offers numerous advantages, including improved performance, enhanced fuel efficiency, and reduced emissions.

An interesting statistic to consider is that CRDi engines have been shown to increase fuel efficiency by up to 25% compared to traditional fuel injection systems, resulting in significant cost savings and reduced environmental impact.